MES systems, i.e. software for monitoring the implementation of the production process

The success of a modern manufacturing enterprise depends on many factors, but one of the key factors is effectively responding to events occurring during the manufacturing process. The ability to optimize production based on constantly up-to-date data leads to improved productivity and efficiency, which translates into business results in the form of increased overall profit. However, this requires an MES system that provides access to real-time information about every stage of production.

Increasing resource efficiency, enhancing the productivity of the manufacturing process, and reducing additional costs that increase the value of the final product are just a few of the many benefits a company can gain by implementing an MES system to support production management. This system serves as a crucial link between production and business, facilitating quick and accurate decision-making thanks to real-time data collected throughout the production process.

What is an MES system?

A Manufacturing Execution System (MES) is an IT solution for monitoring the manufacturing process. It is used to obtain all the information needed to optimize individual operations within the manufacturing process in real time. MES systems rely on IT technologies, control software, electronic devices, and industrial automation components. The interoperability of these components allows for continuous monitoring of the manufacturing process by collecting data from machines, internal logistics systems, automation systems, and direct production, maintenance, and logistics staff. This data is sent to a server, where it is processed into specific messages sent to the ERP system. This information includes information on:

- the degree of use and condition of machines and equipment, as well as their individual components,

- the consumption of raw materials and consumables for completed production orders,

the time taken to complete subsequent stages and operations within the manufacturing process, - service events such as breakdowns or faults causing downtime,

- the number of semi-finished and finished products manufactured.

What is the role of the MES system?

The information provided by Manufacturing Execution Systems (MES) solutions is crucial for the profitability of the manufacturing process. They provide production managers with a realistic picture of the process and the efficiency achieved at each stage. Based on this information, they can take action to optimize individual operations to improve efficiency by reducing costs that don't translate into product value.

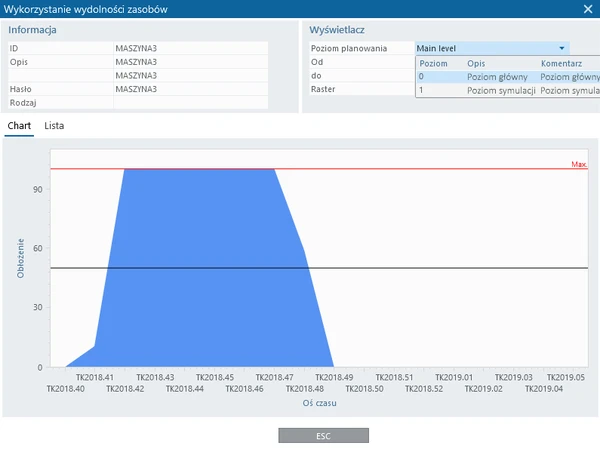

MES simplifies production process management and supports the planning of machine resources needed to fulfill accepted orders. Integrated with machines, it displays current utilization and wear, and whether maintenance is required. As a result, it prevents costly downtime, which is most often caused by sudden breakdowns, excessive changeover times, or excessive machine utilization that prevents the launch of additional production lines.

Which MES software should you choose?

MES systems can function as a connected element of a company's IT infrastructure, be an integral part of a complete production management system, or be a tool with functional scope tailored to the company's individual needs. The choice of solution primarily determines the nature and scope of the manufacturing processes being implemented. MES systems with a very broad functional scope are primarily chosen by companies with extensive production. In situations where there is not a need for all the functionalities of an MES system, a production management system with a functional area for monitoring production execution may be more advantageous. However, where specific, unique processes are implemented, the need to implement a custom-designed tool often arises.

1. MES domain-specific system.

The international standards organization MESA International (Manufacturing Enterprise Solutions Association International) identifies 11 functional areas of an MES system, demonstrating how comprehensive a complete Manufacturing Execution System can be. The functional set of such production monitoring software includes:

- Process Management – ongoing monitoring and coordination of processes and changes based on information about irregularities;

- Performance Analysis – monitoring the performance of machines, lines, and production stations based on information about downtime and progress in order fulfillment;

- Production Tracking and Genealogy (Traceability) – monitoring and recording data that allows for the retrieval of a given product batch. Based on information about suppliers, raw material quantities used, and completed tasks, operators can easily identify the causes of errors and, if necessary, recall defective batches; Quality Management – measurement data from the production process, enabling the assessment of production parameter deviations from the target values and the identification of their causes in order to initiate corrective action;

- Data Collection and Acquisition – generated production reports containing information obtained from machines and equipment, based on which the process can be assessed and optimized;

- Resource Allocation and Status – collection of data on machine and material resources, enabling quick verification of their availability;

- Maintenance Management – information on machines and equipment comprising the production floor equipment, facilitating the planning and execution of maintenance work without impacting ongoing production lines;

- Dispatching Production Units – support in planning tasks between departments to fulfill orders.

The implementation of individual MES functionalities depends on the needs and specific nature of the company. Some are used more frequently, others less frequently. Properly selected, they can actually help improve the efficiency of the production process while utilizing existing resources.

2. MES functional area.

An alternative to the Manufacturing Execution System is production management software with a dedicated range of functionalities enabling production monitoring. An example of such a solution is the TimeLine system, which includes an MES functional area integrated with production resources using the Machine Data Control module. It acquires a range of machine data directly from production stations. This data is collected and processed in real time and then made available in a standardized format in the form of transparent reports. These include:

- machine efficiency at subsequent stages of production,

- occupancy and availability of machines and equipment,

- wear and tear of machines and equipment and their components,

- time of use of machines and equipment in the production process,

- progress of the order being executed,

- duration of subsequent operations,

- quantity and quality of tasks completed in the process,

- number of semi-finished and finished products,

- number of finished products in a given order.

The TimeLine system helps monitor production and manage maintenance. It streamlines the planning of machine resources needed to complete subsequent orders, sets technological standards, and optimizes manufacturing processes. It also facilitates the planning of maintenance, inspections, and modernization, preventing sudden downtime that causes unnecessary production losses.

3. A specialized MES tool.

When the nature of manufacturing processes requires the use of a custom-tailored tool for monitoring production execution within a specific functional scope, flexible low-code technology comes in handy. The nAxiom platform, based on this technology, allows for the rapid development and implementation of custom-designed applications that can be integrated with any software used within the enterprise. Everything is done within a single IT environment without interfering with the structure of domain-specific systems.

With the nAxiom platform, you can build a custom-tailored MES application using pre-built components, reducing implementation time compared to programming. Furthermore, the application can be modified at any time, and prototyping of any modifications is performed without impacting its ongoing operation and process management. The nAxiom platform allows you to create any number of solutions, corresponding to selected functionalities of complex systems or those needed to support unique processes.

How does an MES system differ from an ERP system?

ERP systems used in manufacturing companies integrate and streamline all processes within a company, comprehensively analyzing and presenting information from various departments. Based on this information, operational decisions are made to improve the company's efficiency and, in the long term, achieve strategic goals. One of the most complex and therefore demanding processes in a company is production, the effectiveness of which depends on individual operations and workstations. Evaluating these processes requires access to a wealth of data that a traditional ERP system cannot provide unless it has dedicated MES solutions.

Therefore, an MES system is one of the most important elements of a manufacturing company's IT infrastructure. Through integration with the machinery, it supports decision-making directly related to manufacturing processes, aimed at increasing capacity utilization. It can be integrated with an MRP system, which supports resource management in terms of planning and controlling material levels and production capacity. It can also be integrated with a WMS system, which manages the flow of material resources between the warehouse and the production facility.

Summary

Analyzing key data collected by the MES system directly from production lines allows for informed decision-making, leading to optimal resource management and, ultimately, a higher return on investment. Based on real-time information, it's possible to quickly detect and eliminate potential irregularities, minimize downtime, shorten production times, and reduce labor costs, all while maintaining high product quality. Current data also provides the flexibility to implement changes and adapt production to customer expectations, while historical data allows for optimization of the production technology used.