Simulation of production processes in integrated IT systems

Only a well-planned production process will ensure a final product that meets customer expectations in terms of quantity and quality on time. This will allow the company to fulfill orders without incurring unnecessary costs generated by unforeseen events, ultimately contributing to the expected profit. IT systems with simulation capabilities aid in such precise production organization.

Planning is a very demanding stage of production management, as it determines the efficiency and, consequently, the profitability of the entire process. Therefore, modern IT systems equipped with functionalities that support planners in assessing the company's production capacity are gaining in importance. Solutions that allow for the virtual representation of planned production, such as the TimeLine ERP system, are particularly helpful, facilitating: determining the number of products that can be manufactured within a given timeframe, determining the type and quantity of resources needed (machinery and materials), determining the number of employees with competencies for the required work, and performing preliminary cost calculations for preparing a sales offer.

Production management system

A virtual representation of a planned order allows for effective preparation for the actual production process. Modern software tailored to the needs of a manufacturing company enables simulations for the fulfillment of a complex order. For example, the TimeLine ERP system allows for an automated, thorough analysis of the planned process before production begins. Simply enter the necessary order data to:

- verify optimal resource requirements,

- identify and eliminate potential disruptions,

- calculate order fulfillment costs.

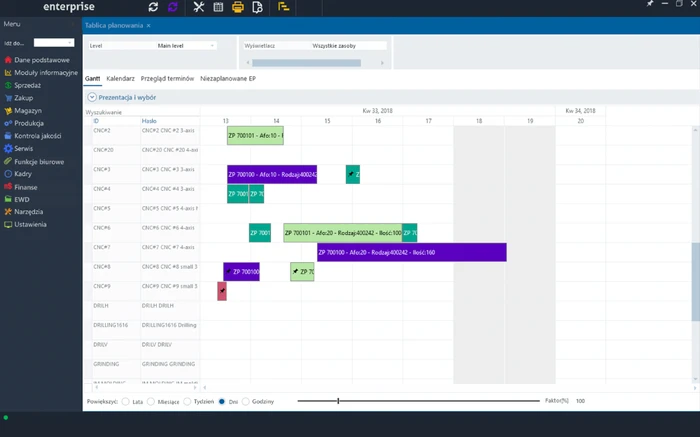

With the TimeLine system, a simulation for a new order can be performed while taking into account the production plan already in progress, without the risk of disruption. When a new order is included in the plan, all orders currently in progress will be postponed. The resulting Gantt chart will reflect the company's actual production capacity and demonstrate:

- how realistic it is to complete the additional order within a given timeframe,

- whether resources will be available to fulfill the additional order,

- whether the additional order will not impact the company's current liabilities.

Ultimately, the simulation will also demonstrate whether the additional order will achieve the expected profitability.

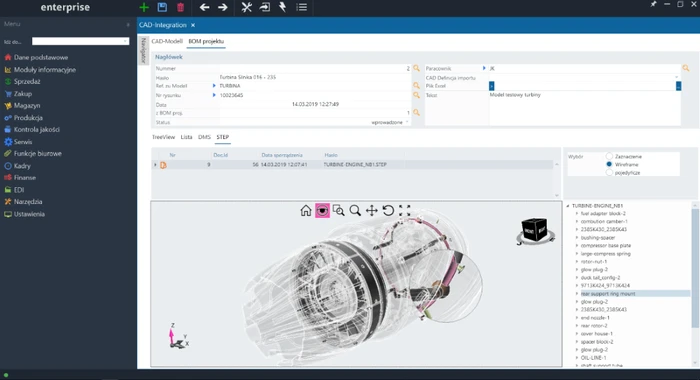

Production order simulation

To simulate a new order, all the necessary data must be entered into the system. With TimeLine, this is very easy and relatively quick. Simply import a list of product components from a CAD file and define the product type – whether it will be a modification of an existing one or a prototype. In the former case, we add the existing technology to the calculation project being created, supplementing it with an additional technology not present in the system but required for product production. In the latter case, all data related to the technology and materials required to fulfill the order for a completely new product must be provided.

Based on the specified technology and materials, the system will automatically create a flowchart for the project calculation reflecting the product's structure. Simply assign a list of the subsequent operations comprising the product's manufacturing process to this flowchart to simulate the order's production. Furthermore, if the order requires collaboration with subcontractors, the system can assign the cost of external services and their completion time to the project calculation. With this information gathered in one place, it's much easier to decide on the subcontractor with the most advantageous offer.

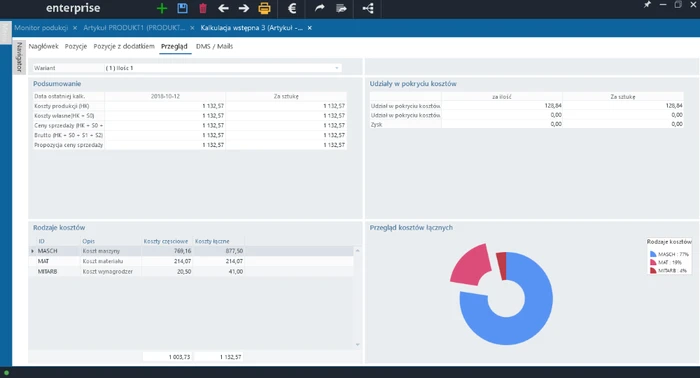

At this point, the system can already define the most important parameters for the order, including:

- machine utilization rate (50% or 100% utilization),

- the cost of purchasing raw materials (broken down by lowest, highest, average, base, last, and main supplier price),

- and the cost of employee time.

This helps prepare a preliminary calculation containing precise information on the partial and total costs for materials and machines, as well as the remuneration of employees involved in order fulfillment. For preliminary calculations for finished product variants, the system allows you to specify different batch values and quantities to recalculate costs. Calculations are made based on the order, taking into account machine setup and preparation times. The situation is slightly different for completely new products, for which calculations must be performed in the system at each production stage.

Once all order-related information has been entered into the system, a production order simulation can be launched. The system allows for monitoring the progress of individual stages and the operations performed during them. After the simulation is complete, it provides actual costs generated during the process, which can then be compared and compared with initial assumptions. After accepting the simulation, simply add the planned order to the master plan, taking into account all resources and deadlines.

Production process organization

Simulation is undoubtedly very useful in the sales and planning stages. It allows for a quick response to customer inquiries, but above all, it provides real data, based on which a realistic valuation can be made, necessary to prepare a commercial offer. Based on the generated results, the system allows for the development of a so-called threshold offer, in which the resulting calculations are multiplied to determine profitability. The system also allows for the preparation of several offers, varying in terms of the number of products to be produced, and therefore also in terms of costs and lead time. This allows the company to propose several options, from which the customer can choose the most advantageous one. The customer's selected offer simply needs to be marked in the system, and the document then receives the status of a completed project and can be forwarded for implementation.

Simulation is useful not only in the bidding and planning stages, but also in production organization. In the TimeLine system, simulation aids in replanning, which takes into account all resources, their types (machines, employees, tools, etc.) or groups (machine groups), as well as the production floor. It improves warehouse and employee time management, simplifies machine park management, and allows for the planning of downtime related to equipment maintenance by shifting work to other, less busy production lines.