What is an MRP and MRP II system? Solutions supporting resource planning in a manufacturing enterprise

Resource planning is one of the major challenges for a manufacturing company. On the one hand, it's crucial to secure materials, as their absence causes downtime, extends lead times, and generates costs. On the other, excess inventory can lead to losses, especially in project-based production. The plant must order raw materials on time and in quantities appropriate for the project, and also maximize the production capacity of machines, equipment, and people.

Optimal resource planning significantly impacts production efficiency and order profitability. This is particularly evident in the case of complex products with many different variants, or non-standard products made to order.

Production resource planning and order profitability

In the case of complex products manufactured in many variants, a plant faces a large number of different types of materials delivered at each stage of the manufacturing process. In contrast, the challenge of custom production is the different type and quantity of raw materials for each new order, which requires continuous process planning. Long production cycles, especially those carried out with interruptions, are also a challenge for many companies.

In each of these situations, the plant must closely monitor production progress, including the production of semi-finished products and the materials used, taken from the warehouse. The timing of the order for the raw materials required for each stage is crucial – deliveries must arrive in accordance with the planned production cycle, but also not too early to avoid inventory lag. Another key issue is the appropriate utilization of the production infrastructure in the planned product manufacturing process.

Material Requirements Planning (MRP) – What is it?

For many years, MRP systems have helped companies manage resources optimally – preventing unnecessary costs and ensuring production profitability.

The first material requirements planning systems were purely planning solutions, covering production only. However, this quickly became insufficient to maintain competitiveness and profitability in today's market conditions.

Therefore, MRP served as the basis for the creation of ERP and MRP II systems – enterprise resource planning (ERP) and manufacturing resource planning (RMP). These systems manage the use of not only materials, but also time, money, and fixed assets, as well as the capabilities of machines and employees at specific workstations.

The MRP II system is now an integral part of the IT infrastructure of manufacturing companies. It is either a standalone, standalone solution or a tool embedded in a specialized, comprehensive system – such as the TimeLine production management software, which effectively combines the functionalities of MRP, APS (supply chain management), MES (real-time production management), QC (quality control), and BI (business intelligence).

What is MRP I and why is it not enough?

1960s, United States. The American Association for Production and Inventory Control (APICS) creates the first basic MRP system and its standard. It covers production management, but only in terms of material flow – availability in warehouses and demand during order fulfillment. This facilitates the preparation of bills of materials and components required for each stage of the manufacturing process.

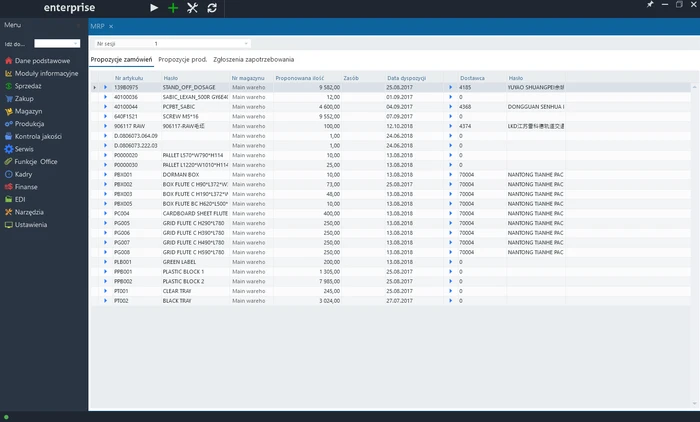

A plant using one of the first MRP systems determines its demand based on the projected demand for a given product, primarily taking into account the number of production orders placed to date. It calculates the required raw materials based on bills of materials (BOMs), which list all the raw materials needed to produce the final product. To determine material requirements, it checks inventory levels, excluding available raw materials and placing orders for those missing. It sets purchase deadlines to ensure the necessary materials are available for each stage of the production process.

This first, basic MRP system allows the company to:

- ensure a minimum inventory level for order production;

- reduce material holdings in the warehouse;

- shorten the waiting time for material deliveries;

- prevent production downtime caused by raw material shortages.

From the 1960s to the 1990s, MRP systems primarily facilitated the calculation of material quantities required for each production stage. They also allowed for adjustments to production assumptions based on order fulfillment.

However, market demand increased, competition emerged, and plants had to focus on process efficiency. They had to create a production plan that also considered supporting materials, human resources, money, time, fixed assets, and other factors.

In 1989, APICS announced the "MRP II Standard System" – guidelines for new, second-generation MRP systems that focused beyond the management of materials required for production.

What is MRP II?

The essence of an MRP II system is best captured by the new acronym that defines it – "material requirements planning" has been changed to "manufacturing resource planning."

The creators of MRP II systems retained the existing functionalities related to material planning, but also introduced new ones addressing other areas crucial to the efficient organization of the manufacturing process.

From now on, MRP II software providers consider resources not only raw materials needed for production, but also all process components necessary for product production. This approach leads to the development of complex capacity planning systems that incorporate a range of data related to the availability of employees, machines, and equipment, as well as the assessment of financial resources. Optimizing production processes with the help of an MRP II system involves combining activities at both the planning and control levels, taking into account the availability of resources at every stage of the individual processes.

By implementing an MRP II system, the plant can significantly more easily:

- manage material purchases;

- plan production;

- control production flow;

- schedule production;

- track material needs;

- plan sales;

- manage orders and fulfillment;

- organize supplies;

- manage costs;

- measure production results.

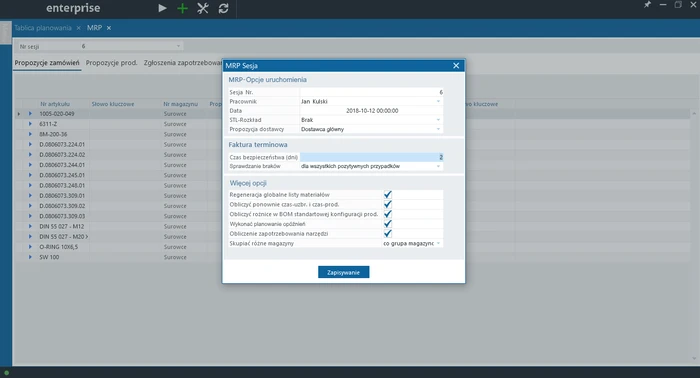

In MRP II systems, the plant plans production and schedules purchases based not only on existing and forecasted demand, but also on the entire production process.

The database therefore comprises information on, among other things, orders, potential sales opportunities, product structure, and the manufacturing process. Based on this information, the plant can precisely determine the required resources – material, machinery, and human resources. It can accurately assess production capacity in terms of inventory levels, machine utilization, and employee availability – and indicate at which production stages specific resources will be needed.

The starting point is still the raw materials bill of materials (BOM), but it is supplemented with a list of operations for a given order and a master production schedule (MPS), in which the plant details the size of the order, the amount, and the product availability date.

What benefits does the company gain from implementing MRP II?

The MRP II system allows a company to optimally utilize its material resources, taking into account the availability of machinery, equipment, and staff. It helps shorten production cycles and improve the profitability of the manufacturing process, thus generating the highest possible profit without exceeding the established budget.

Examples of MRP II system functionality

- A plant determines actual material requirements and the deadlines by which it must have raw materials to complete subsequent stages of the production process without costly downtime. Orders are fulfilled according to the quantities planned in the schedule.

For example, in the TimeLine ERP system, the employee responsible for purchasing plans orders based on the dates assigned to the operations relevant to a given order. If the delivery date changes, this information is automatically updated for all related orders. This significantly improves the company's production continuity.

- The plant tracks the availability of raw materials needed for the production process and responds quickly to any changes. For example, TimeLine ERP provides resource information based on material serial numbers for each warehouse operation.

The company benefits from implementing a system that supports resource and capacity planning, including:

- reduces inventory;

- has constant access to materials needed for production;

- prevents delays in the production process;

- precisely determines raw material quantities and delivery dates;

- manages supplier relationships more easily;

- shortens order fulfillment times;

- reacts more quickly to potential changes due to early warning.

The MRP II system gives the plant full control over the flow of materials and their inventory, and also allows it to better utilize manufacturing resources – ensuring the continuity of the production process. This, in turn, reduces the cost of losses by eliminating their causes, such as raw material shortages at various production stages, inefficient machine utilization, or excess inventory.

Summary

The MRP II system is a comprehensive solution that supports the organization of manufacturing operations. Although its primary function is to support material resource planning and production capacity, it also encompasses activities related to production control, performance measurement, and sales. It also allows for a faster response to rapidly changing customer needs. This increases company efficiency and helps achieve and maintain a high level of competitiveness in today's demanding market.

FAQ:

1. MRP System – What is it?

MRP systems are material requirements planning systems. They have been replaced by a new generation of systems – MRP II: manufacturing resource planning.

2. What is the difference between MRP and MRP II?

MRP II systems retain the functionality of first-generation programs but have been expanded to include capacity planning, sales support, and management decision-making. They take into account not only materials needed for production, but also human resources, equipment and fixed assets, time, and money.

3. How to implement an MRP II system?

MRP II can be implemented as a standalone solution or as a tool embedded in a specialized production management program, such as TimeLine.