IT systems in poduction. What IT solutions do companies expect?

Technological advancements in production facilities encompass not only manufacturing technology but also the IT tools that support this process. Computerization is a key factor in a company's development and competitiveness in the market. Therefore, investing in IT solutions has become a necessity.

Investments in computerization in the production area are primarily driven by the desire to increase profitability by improving the efficiency of manufacturing processes and optimizing related costs. This leads to the implementation of an increasing number of dedicated systems that enable the acquisition and comprehensive management of information across the entire production area.

IT tools supporting production

Modern IT systems currently in use comprehensively support the entire production coordination process. They are used at the sales stage to process inquiries, preliminary cost calculations for offered products, and order acceptance. They support the manufacturing process itself, including resource planning, production scheduling, machine and order status monitoring, and quality control. They also streamline sales and logistics. Specialized tools with strictly dedicated functionalities are gaining in importance, as are flexible solutions that offer extensive integration options with the core software that constitutes a company's IT infrastructure.

1. Simulating production on schedule.

The profitability of the production process depends largely on whether the cost of order fulfillment is correctly estimated at the order acceptance stage. This requires taking into account many factors, which are unfortunately difficult to predict. Therefore, simulation of the manufacturing process is crucial at the initial cost calculation stage, and should be enabled by a production management system. The simulation will show what will happen when production of a new product is launched. It will provide answers to key questions:

- What will the planned production cost be?

- What is the likely order completion date?

- How will the new order impact the current production?

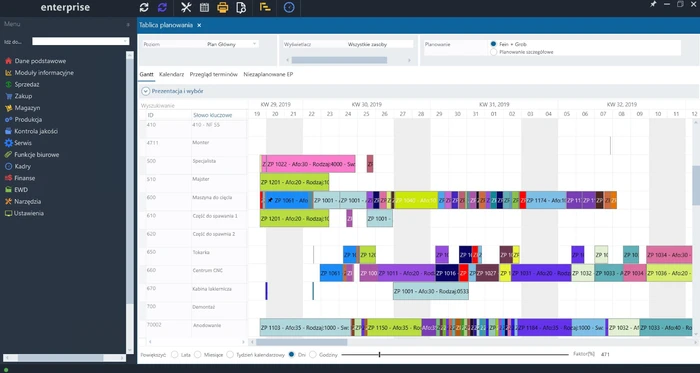

Additionally, using simulation-enabled systems allows us to obtain information on resource utilization—human, material, and machine. We also gain insight into the execution process itself. Simulation allows us to assess the actual cost of a potential order, and then quickly prepare a preliminary calculation based on it, necessary for submitting a quote. In the TimeLine ERP production management system, such simulation is performed on the current production plan, but without interfering with current orders. Its progress is reflected in a Gantt chart, which shows actual production capacity. Once the simulation is completed and approved, the new production plan is automatically applied to the master plan.

2. Efficiency monitoring.

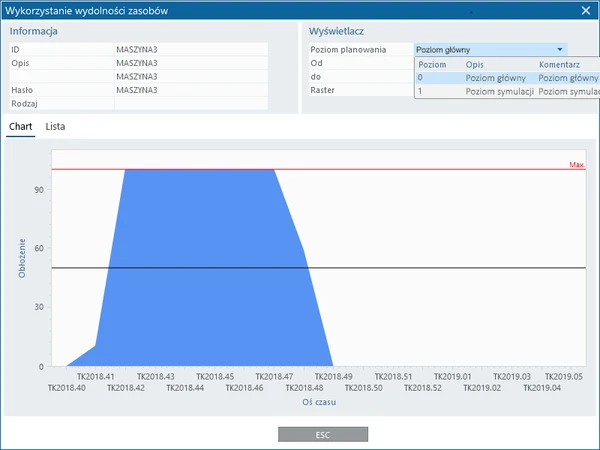

For the efficiency of the manufacturing process, it is crucial to monitor what is happening on the production line in order to react quickly and make the right decisions at the right time. Information about production progress is provided by the MES system, which provides precise information about the progress of the order fulfillment process. By integrating the MES with the machine, the progress of the order fulfillment is recorded in real time and includes operations performed at subsequent stages of the manufacturing process. All data is continuously obtained directly from the production stations, therefore, it is precisely known which components were produced, in what quantity, and at what time. Furthermore, the MES system provides information on resource utilization and material consumption, which helps in the optimal use of available resources.

In the case of the TimeLine ERP system, of which MES is an integral component, maintenance operations are facilitated by graphical monitoring of resource utilization. By providing control over the production process, MES increases productivity while simultaneously reducing the time and costs associated with order fulfillment.

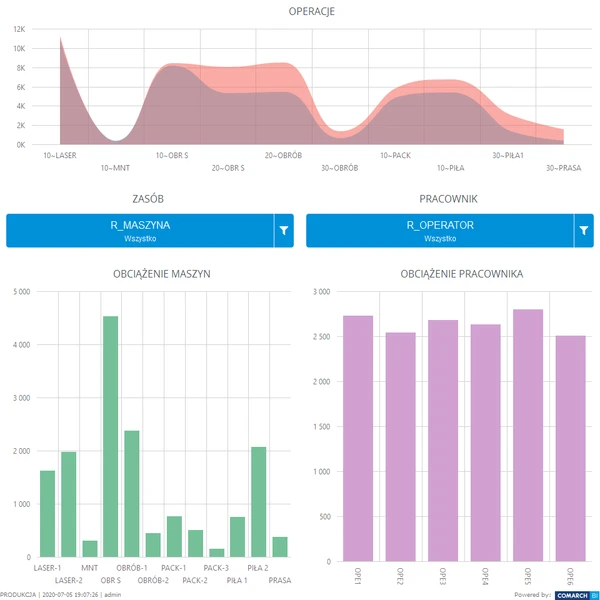

To ensure the profitability of the production process, ongoing monitoring and analysis of performance indicators is also crucial. Hence, investments in Business Intelligence tools enable increased efficiency of production lines and even entire factories. Integrated with systems such as APS, MES, MRP, and other production management software, they acquire and analyze data in real time. And the more systems used, the more data is processed, providing the results needed to evaluate numerous key indicators. Business Intelligence tools enable, among other things:

- reducing production costs by identifying their causes,

- maintaining control over performance by identifying areas requiring improvement,

- improving production processes by identifying the causes of problems and implementing rapid corrective actions.

Comarch BI Point is a business intelligence tool that can be used by manufacturing companies. The software provides continuous access to current data, but also provides insight into historical data. By comparing current analysis results with historical ones, you can draw numerous conclusions necessary to optimize manufacturing processes.

3. Flexibility of IT solutions.

With the need to quickly respond to changing customer needs, flexible solutions are becoming increasingly important, allowing companies to quickly adapt to dynamic market realities. A low-code platform provides companies with maximum flexibility in expanding and improving their existing IT infrastructure. It enables the rapid modernization of existing applications or the creation of entirely new ones dedicated to unique processes.

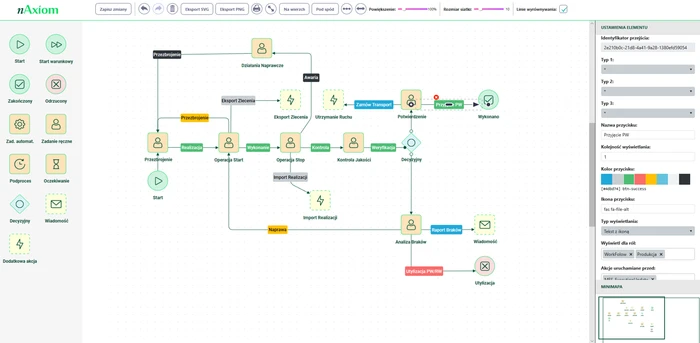

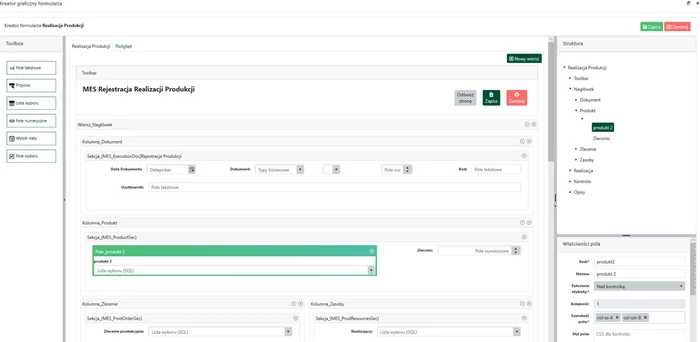

What does this look like in practice? Let's take a look at the Naxiom platform as an example. Application design and development is performed using drag-and-drop methods and involves combining pre-built components available within the platform. The workflow is presented in a visual interface, where instead of traditional code, a diagram of the application being created is visible. This minimizes the amount of coding work, which is primarily devoted to the solution's functionality. As a result, the application is developed faster and at a lower cost. Using a low-code platform, the ergonomics of managing a modern production facility can be significantly improved.

Example:

We implemented the above scenario for a client operating in the metalworking industry. The sales process begins with a market inquiry, which is then forwarded to the design department, where TimeLine gathers comprehensive information – including possible completion dates and potential costs. Based on this data, a decision is made on the feasibility of pursuing a given project, taking into account margins and the impact on other orders. Therefore, we also utilized the nAxiom platform to combine all applications required for the smooth execution of this process into a single, coherent mechanism.

The low-code platform enables the efficient creation of new tools by users with subject matter expertise. This allows for rapid modifications to production monitoring and management in response to necessary changes implemented due to changes in orders, technological processes, or organizational conditions. This approach facilitates maintaining a high level of competitiveness.

The TimeLine ERP production management system also aligns with this trend of "flexibility," featuring a built-in Rapid Customizing RAD development tool. The idea is to give users the ability to independently customize the software to their needs, for example, by adding elements such as tabs, forms, or buttons. This is precisely what TimeLine does, where the Rapid Customizing RAD tool allows users to create and modify elements within the interface, reports, and database.

It's also worth noting that almost everyone interested in modern production plant management emphasizes the openness of the interface and multi-way communication. Flexibility in integration, particularly with CAD software, is also important, as is the ability to manage imported data in the ERP system. This significantly reduces the time it takes to prepare production order processing technology.

Example:

A client from the manufacturing industry decided to implement the software because they needed CAD integration, as well as the ability to store all technical documentation connected to a production management system.

Comprehensive IT support

Manufacturing companies' expectations are changing not only with regard to tools and technologies, but also with regard to the nature of IT support for production management systems. Therefore, the goal is not to focus on a single system, but on multiple solutions that, when combined, create the IT infrastructure needed to efficiently manage the entire production process. Because production planning and scheduling are so important, the most sought-after solution is an APS, which must be equipped with a smoothly functioning production system.

Example:

For a client manufacturing machinery and equipment for the food industry, we implemented APS functionality to optimize order planning for internal customers – the parent company. This allowed us to identify production potential and the possibility of additional utilization of the production line for external customers – clients not previously served.

In addition to APS, an MES system is crucial for collecting information on production execution. Real-time data significantly impacts the ability to intervene and adjust production plans.

Example:

In a project for a client in the furniture industry, we focused on a single, simple interface for recording the work of individual teams working on a given order – additionally enhanced with the ability to conduct random quality checks.

Analytical tools that allow for early verification of assumptions against final results are equally important, thus increasing production profitability.

Furthermore, rapid access to information needed at every stage of decision-making is crucial for production plant managers – whether related to proper inventory management, cost estimation, or the optimization of human resources or technological resources. Therefore, precise monitoring of process conditions and the ability to work with large amounts of acquired data become crucial. This, in turn, requires the use of various IT tools – specialized production systems, IoT solutions, and flexible low-code platforms.

However, to achieve the expected OEE indicators or properly defined KPIs, the implementation and integration of individual solutions enabling the acquisition of data from work in progress must be meticulously carried out. Mechanisms must also be in place to efficiently respond to any discrepancies and effectively implement necessary changes. This applies to the planning, optimization, and execution of the manufacturing process. Similarly, to improve product quality and, consequently, minimize the number of complaints, a well-managed quality control process is essential. Dedicated solutions will allow for quality monitoring at every stage.

Podsumowanie

The manufacturing industry is increasingly investing in specialized tools to complement standard solutions that comprise a company's IT infrastructure. Furthermore, trends, largely driven by market conditions and growing competition, drive the need for continuous productivity improvements, which prompts the search for ever-increasing solutions to streamline operations. Recognizing these interdependencies, we offer tools for managing all elements of the production process. In the production area, we rely on the Timeline ERP system, which includes both APS and MES, quality control, and proprietary analytical tools. We also provide our own low-code platform, nAxiom, enabling independent application development and process digitization. We utilize RFID technology and implement solutions supporting logistics processes, including WMS systems and BI analytical platforms. We provide comprehensive tools to support the management of a modern manufacturing enterprise.