Low-code technology. On the (r)evolution of IT solutions for manufacturing companies – part 3

For modern businesses, the continued development of software is crucial, especially given the rapid pace of market change we're currently experiencing. Manufacturers understand this situation perfectly and are therefore constantly improving their solutions. However, can core ERP systems and other domain-specific systems become flexible enough to meet individual business requirements? Does such flexible technology even exist?

In addition to ERP systems that streamline management processes, manufacturing companies also utilize specialized systems that support manufacturing processes. These include MES, MRP, APS, and WMS systems, which provide a wealth of data processed by Business Intelligence systems. A manufacturing company's IT infrastructure therefore consists of numerous integrated IT solutions. Even if these systems are fully utilized in specific areas, there are still unique or new processes that require automation. Implementing this automation in practice proves difficult, primarily due to the lack of appropriate tools.

Despite updates in functionality and integration capabilities, both ERP systems and domain-specific systems remain universal software. They comprehensively meet standard needs common to all companies, but they no longer offer the ability to customize them to individual requirements. Therefore:

- What about companies that implement specific processes as part of their operations?

- What about situations where the rapid pace of change requires immediate implementation of solutions?

- What about manufacturing companies for which basic solutions are insufficient?

Native IT solutions

To meet the expectations of today's enterprises, ERP and other domain-specific systems manufacturers provide native solutions. Built from scratch for specific software, they allow for better utilization of existing functionalities. However, launching a dedicated solution, tailored to the software and the company's needs, is usually time-consuming and expensive. Unfortunately, it often turns out that by the time the months-long development process is complete, processes have changed so significantly that the solution no longer meets the company's expectations. As a result, the solution needs to be updated – which again requires time and expense – or implementation is abandoned altogether in favor of other off-the-shelf tools available on the market. While launch and integration times will be shorter, they will still not fully meet the company's individual needs and will eventually require costly modernization. Necessary updates or dedicated tools cannot always be delivered in a timely manner to meet changing requirements.

Software development is therefore a very slow process, even though the changes facing companies are dynamic and complex. Therefore, native solutions are difficult to fully flexibly understand as the ability to quickly implement technological modifications. So, what options do companies with specific or rapidly changing processes have?

Low-code solutions

Platforms based on low-code technology offer significantly greater flexibility than native solutions. They offer extensive customization options, allowing them to meet the most individual digitalization needs of enterprises. They enable rapid process automation and provide a sense of control despite dynamically changing business conditions.

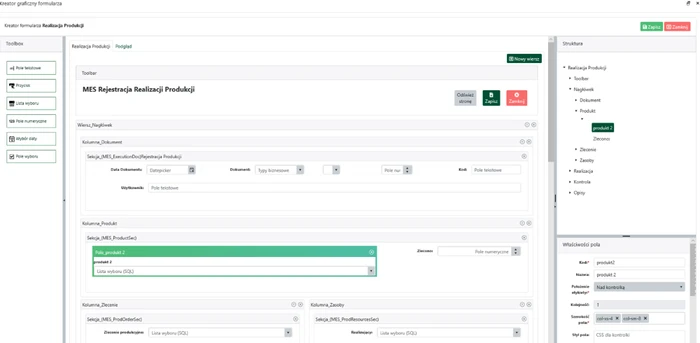

An example of such a solution is the nAxiom platform, where tools are created in an agile, visual manner. Work is carried out from an intuitive graphical interface using drag-and-drop and a limited amount of code. Advanced programming knowledge or the involvement of development teams is not required. Collaboration between developers and users of the designed application is sufficient. The former focus on the mechanism of operation, while the latter are responsible for modeling the process, defining subsequent steps and actions. The application is built from pre-built components, and the graphical interface displays the results in real time. If modifications are necessary during the process, any required changes can be made immediately. This shortens the time required to implement a custom-tailored tool, and allows the company to more efficiently adapt technologically to dynamic market conditions. Furthermore, applications created on the low-code platform are not only easy to launch but also to develop and maintain. Updates are implemented directly in the production environment, without the risk of disrupting the continuity of processes and the operation of the underlying software, such as the ERP system. And because the platform is scalable, it allows for continuous expansion to meet the emerging needs of businesses in the future.

Unique business applications

Using an advanced low-code platform, even highly complex and functional tools can be created. The more components and connectors a low-code platform has, the more tools and integrations can be created. Custom-tailored applications allow for additional connections within the machine park – between production lines and machines. The ability to quickly build and easily develop customized tools prevents losses caused by the inability to quickly respond to changing conditions. At the same time, the total cost of implementing and maintaining low-code tools is lower than the cost of tools delivered using standard coding techniques.

A low-code platform is based on generally accepted programming standards. Therefore, applications created with it will be compatible with existing systems, providing unlimited integration possibilities. Furthermore, building and using applications is possible regardless of the operating system used (Windows, Linux, etc.).

Low-code technology offers complete flexibility, ensuring businesses can grow by implementing the necessary IT tools when needed. This doesn't mean, however, that such solutions will replace ERP systems. However, they will allow companies to agilely adapt to changing market conditions by providing complementary business applications.

Summary

Having technologies that increase a company's flexibility in its processes is a prerequisite for effective digital transformation. This doesn't involve operating based on a single system, or even several interconnected systems. It also requires the use of a wide range of individually tailored solutions, integrated into a single, cohesive environment. This is where the low-code platform breaks down technological barriers, becoming a (r)evolution in the field of computerization. It allows for the automation of various areas of operation by creating dedicated tools integrated with any software. In the era of digital transformation, low-code technology is therefore a necessity, increasing the chances of building a competitive advantage. Thanks to it, there is no longer a need to adapt processes to ERP and domain-specific systems, but rather the freedom to develop the organization according to emerging needs.