ERP Systems. On the (r)evolution of IT solutions for manufacturing companies – Part 1

Enterprise-class IT solutions for managing manufacturing company resources are now not a matter of choice, but a necessity that determines business efficiency. Without dedicated technological support, it is virtually impossible to effectively coordinate processes related to the ever-increasing market demands.

ERP solutions that support decisions in various areas of business have existed and have been used for many years. For companies that, for various reasons, are not fully utilizing their potential and are focusing solely on selected modules, these solutions are usually sufficient. The situation is somewhat different for companies that, due to their gradual growth, have quickly implemented the full range of system functionalities.

Next-Generation Domain Systems

Currently available domain systems are new-generation solutions, largely aligned with the concept of Industry 4.0. Thanks to dedicated functionalities, they support the management of numerous processes across various production areas and the entire enterprise. They enable the management of vast amounts of data – organizing and streamlining its flow within the enterprise. They enable the seamless exchange of information within a given area and between all departments within the company. All this is done in real time.

An example of such a solution is the TimeLine manufacturing ERP system, built from modules grouping functionalities that precisely meet the needs of manufacturing companies. On the one hand, this software is universal, as it can be used by companies from various industries (automotive, foundry, etc.). On the other hand, thanks to the implemented solutions, it can be tailored to the specific profile of the business.

However, due to the dynamic changes taking place in today's market, many companies constantly need additional IT solutions. This is particularly evident in industries with unique business profiles, where, in addition to the core IT system, additional solutions are required to support specific processes specific to the company's profile. The situation is similar in rapidly growing companies, where it often turns out that at some point, the company's needs exceed the standard capabilities of available IT solutions, including ERP systems.

Integration of multiple IT solutions

Development and implementation teams address these business needs by delivering software and integrating it with the ERP system. This provides companies with solutions tailored to their business expectations while simultaneously leveraging existing "core" solutions available in ERP systems.

In modern manufacturing companies, it is now standard to have an IT infrastructure comprised of several integrated systems that, through collaboration, enable the efficient management of an increasing number of processes. These systems typically consist of:

- An ERP system – with a range of functionalities designed specifically for key processes occurring in specific areas of the company.

- An MES system – combining automation with IT technology, enabling machines and software to form a single, cohesive system that provides full insight into the ongoing process, enabling monitoring and coordination.

- An MRP system – enabling realistic production capacity planning, taking into account all necessary resources, such as available raw materials, machinery and equipment, employees, and the time required to complete an order.

- An APS system – enabling automatic production planning, taking into account available resources, enabling rapid response to market needs.

- An WMS system – ensuring control over the flow of goods in the warehouse and facilitating their rapid location.

- An PDM system – streamlining documentation management and providing access to project data.

Combining multiple specialized solutions with functionalities specific to various production areas allows for the creation of extensive IT ecosystems that meet the growing needs of modern enterprises.

A complete production management system

However, changes in IT solutions for manufacturing companies have not stopped at the integration and construction of multifunctional ecosystems. They have also become a stepping stone to the ongoing evolution of domain-specific systems. Modern production management software combines the features of the above-mentioned solutions. For example, the aforementioned TimeLine system is equipped with key production functionalities typical of MES, MRP, and APS systems. Additionally, quality control, analysis, and reporting modules are integral components.

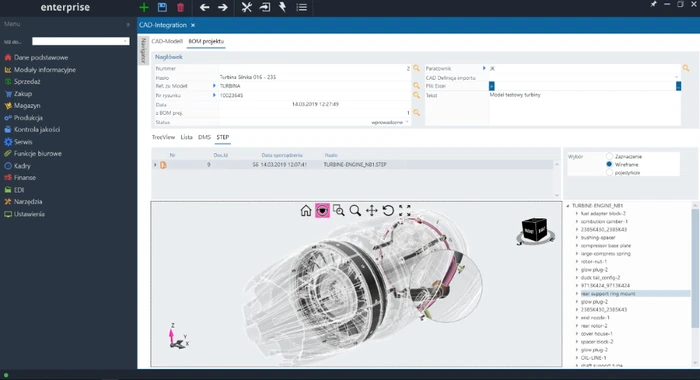

Moreover, the ability to integrate the ERP system for manufacturing with CAD software has become a significant (r)evolution. Combining both tools allows for automatic data exchange during both the product design and manufacturing stages, significantly improving production efficiency. In TimeLine, CAD data management is facilitated by the PDM system, an integral component of the manufacturing software. It allows for native 3D visualization with Pan/Zoom/Tilt from STEP or IGES formats and their automatic generation from drawing files. It ensures synchronization of metadata containing assumptions and technical specifications. This central archiving of design documentation provides access to data about the manufactured product to all involved at every stage of implementation.

Another (r)evolutionary feature of a modern production management system is the ability to introduce certain modifications. TimeLine software, once again an example, thanks to its built-in developer module, allows for the quick editing of production modules with new features. Using a dedicated update manager, administrators can independently modify report templates, add elements to the interface, and create new objects in the database. Managing official and modified versions ensures the stability of the entire system.

Summary

ERP systems have undergone a (r)evolutionary change since their introduction to the market. They have become specialized and have gained a range of functionalities enabling the complete management of specific areas of the enterprise. The market is undoubtedly the driving force behind these successively implemented changes, determining the directions of development. What will these changes look like? Finding solutions that can be quickly adapted to continuously implement newly emerging processes is becoming crucial today.