Business Intelligence Tools. On the (r)evolution of IT solutions for manufacturing companies – Part 2

To remain competitive in the market, companies must continuously monitor and analyze process conditions and skillfully manage acquired data. Therefore, alongside dedicated ERP systems, Business Intelligence tools are crucial, as they process the information needed to measure efficiency at every stage of operations in real time.

For business analytics to be effective, it's essential to focus on multiple aspects of a business. This requires collecting and processing vast amounts of data from as many different sources as possible. Because businesses now rely on the internet, detailed, real-time data is accumulating rapidly. This data allows for the construction of a realistic picture of the conditions for ongoing processes, providing the basis for analysis:

- predictive – forecasting possible events based on current and historical data,

- forward-looking – defining the most accurate actions based on data to achieve goals.

Therefore, modern enterprises are turning to analytical and reporting Business Intelligence tools. Combined with solutions from the Internet of Things (IoT), these tools lead to the emergence of large data sets – Big Data. IoT and Big Data are closely related to Industry 4.0, driving (r)evolutionary changes in BI tools and dedicated ERP systems.

The internet of things in industry

The Internet of Things refers to a network of intelligent devices that communicate and exchange information via networks, all without human intervention. IoT solutions are used in many areas of the economy, including industry. In this case, the Internet of Things consists of interconnected systems:

- IT systems – responsible for process planning and management,

- operational systems – responsible for monitoring and controlling devices.

Industrial machines are equipped with devices such as sensors, readers, and data acquisition sensors, as well as radio components that enable data transmission via the internet. Data transmission can be performed using wired Ethernet or wireless technologies – Wi-Fi or Bluetooth.

The more IoT devices there are within a machine park, the more data is generated, which constitutes vast collections of data, known as Big Data. The information collected and transmitted is sent to the main IT solution, which serves as a central database – typically an integrated ERP system, which:

- must remain efficient as data grows,

- ensure automatic data analysis in real time.

The data collected in this way is stored on a server or in the cloud. Because it comes from various sources, it is unstructured. Therefore, for it to be processed effectively, it must be standardized, i.e., given a consistent format. Therefore, it is essential to configure the ERP system and a Business Intelligence tool that will unleash the potential of the collected data through real-time analysis, transforming it into readable reports.

Analysis with Business Intelligence

Initially, business intelligence solutions were primarily used for data collection and served solely as information repositories. Over time, they evolved into analytical and reporting tools that processed information in real time. However, just a few years ago, the reports generated were pre-defined during a time-consuming implementation process. Despite the associated costs, management decided to use these solutions, aware of the resulting benefits for the operation and development of the company.

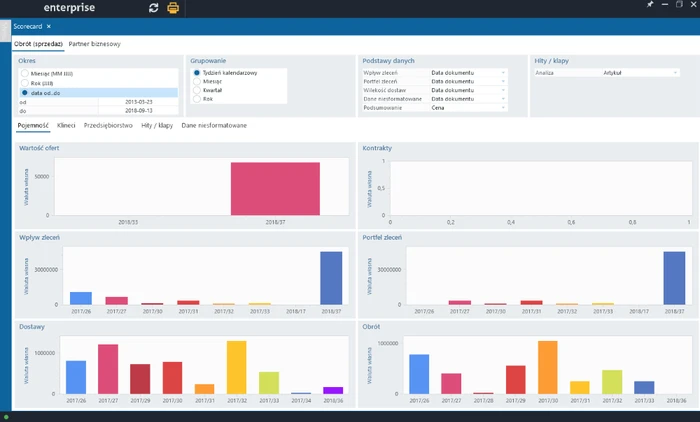

Over the past few years, the field of Business Intelligence has undergone a (r)evolution. Some available tools operate as standalone solutions that can be integrated with any software used within the enterprise. An example of such a solution is Comarch BI Point, which can be integrated with various software. BI tools can also be an integral element of an ERP system suite. This is the case with the TimeLine production management system, which includes BI Power Pivot.

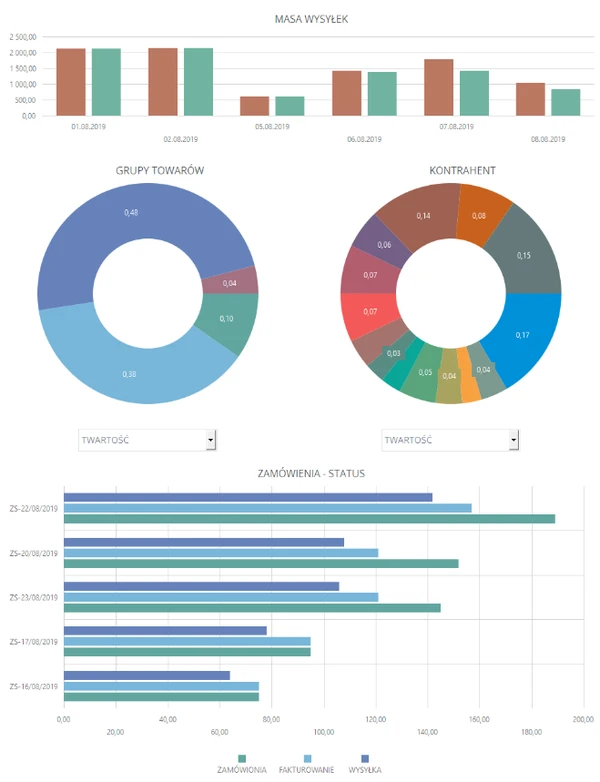

Currently available BI tools not only deliver real-time reports but also enable the flexible adaptation of analysis processes and generated reports to changing business needs. Modifications are made easily and intuitively. Users have access to configurable dashboards, within which they can create dedicated data visualizations using charts, tables, and diagrams. For example, Comarch BI Point allows for the creation of advanced visualizations presented in interactive dashboards, which can be easily customized to individual preferences thanks to the Drag&Drop technique. The BI tool in TimeLine ERP, on the other hand, allows for the personalization of key key performance indicators in dashboards. Using the report designer, the user can modify the available templates, but also create completely new ones.

Simply select a data source to run a BI analysis for a selected process and receive a report in the specified format. Access to information is possible from anywhere thanks to BI tool interfaces adapted to mobile devices such as tablets and smartphones, which are as intuitive to use as on desktop devices.

The foundation of Business Intelligence tools is providing users involved in business processes with quick access to information. The goal is to minimize the waiting time for analysis, resulting in a clear report that allows for quick interpretation and conclusions. Furthermore, such solutions enable the creation of a shared workspace for all authorized users, significantly accelerating information exchange.

BI combined with IoT

Analyses performed and reports created in the BI tool, based on data provided by IoT solutions, provide information on numerous activities within the production area and other related departments of the company. The collation of this diverse data enables the identification of interdependencies between individual processes. This facilitates monitoring and assessment of the situation, rapid decision-making, optimization of individual operations, improved operational efficiency, and cost reduction.

Examples of the use of BI tools and IoT solutions in manufacturing include:

- Machine health monitoring – alerts regarding upcoming maintenance, wear, or damage to components to prevent breakdowns and the resulting costly downtime;

- Inventory control – automatic notifications regarding the type and quantity of resources required for an order;

- Quality control – detecting irregularities in components and semi-finished products, eliminating the risk of producing defective batches;

- Machine operation log – monitoring resource utilization in a given production process, enabling optimization of the production process sequence.

BI tools combined with IoT solutions provide significant support for planners, who can determine the optimal process flow based on data from various production areas. This is possible thanks to the TimeLine ERP system, which, through simulation, allows for the development of manufacturing process scenarios for various orders. Based on these scenarios, the type and sequence of resources used can be determined, ensuring not only a quick response to orders but also rapid order fulfillment. All of this is achieved using a wealth of data provided in real time. The BI tool in TimeLine ERP provides full verification of the plan's assumptions against the current state of the manufacturing process.

Summary

BI and IoT solutions enable more effective management of operational processes. Decisions are made consciously based on detailed, real-time data, which facilitates both the assessment of the current situation and the prediction of trends and development directions. The vast amount of this data and the associated advanced analyses require high flexibility from Business Intelligence tools. It is also crucial that modifications can be implemented immediately by users themselves, without the need for time-consuming system redesign. Only in this way, as more and more information is acquired, it will be possible to continuously monitor and precisely verify the conditions of process implementation.

Modern enterprises seeking to remain competitive must efficiently manage information. Modifiable BI tools truly facilitate this process. However, there are still areas where flexible solutions created using intelligent technologies are necessary to implement often unique processes.