Predictive maintenance, or how to prevent production losses

Production losses stem from, among other things, maintenance incidents, which cause unforeseen and unfortunately costly downtime. The more frequent and prolonged these incidents are, the more unprofitable manufacturing processes become. Therefore, well-organized maintenance activities are crucial to ensure production continuity.

Maintenance involves ensuring proper and properly functioning technical infrastructure—machinery, equipment, and all installations—for production. Related activities include equipment registration, spare parts procurement, inspections and maintenance, troubleshooting, and modernization to improve existing solutions. From this perspective, maintenance boils down to preventing service incidents based on scheduled equipment condition inspections and quickly eliminating failures when they occur. However, predictive maintenance, based on data obtained from the production area using IT technologies, is gaining popularity.

Machinery and equipment condition assessment

Predictive maintenance is associated with the development of modern technologies enabling data collection and analysis. It involves adapting maintenance activities to the current condition of machines and equipment, as well as detecting potential threats before they occur. The difference from the traditional approach, therefore, lies not so much in planning maintenance work according to a pre-defined schedule, but in monitoring the situation and intervening at the first signs of wear and potential failure or malfunction. Therefore, predictive maintenance strives to minimize service incidents, which, despite a rapid response, invariably result in losses with the traditional method.

Monitoring production parameters

A reliable assessment of the condition of machinery and equipment based on regularly collected and analyzed production data allows for the accurate identification of potential threats caused by component wear or visible signs of damage, even before service events occur. The more data collected, the more accurate the analysis of potential threats resulting in downtime. Therefore, predictive maintenance requires IT solutions that monitor the performance of machinery and equipment, as well as the condition of their components. Such tools help in:

- defining the types of possible service events,

- assessing the risk of such events and their frequency,

- determining the causes and circumstances of event occurrence,

- recognizing patterns of potentially hazardous situations.

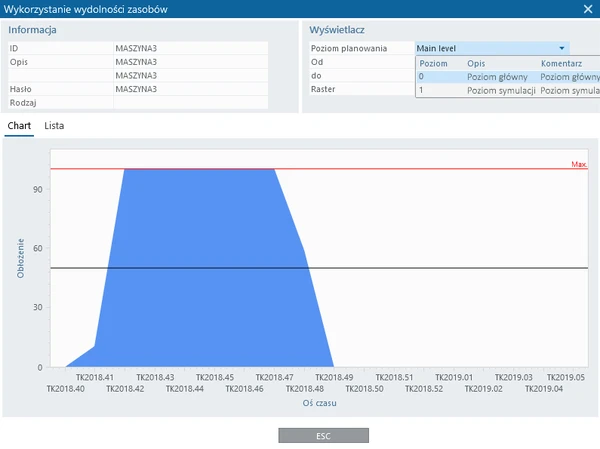

An example of software enabling real-time monitoring of machines and devices is the TimeLine production management system with a built-in MES functionality. Integrated with machines and devices via the Machine Data Control module, it collects and processes data in real time, providing it in a standardized format in the form of easy-to-read reports. It provides:

- data on machine operating time, status, and utilization;

- machine efficiency measurement at subsequent production stages;

- data on machine utilization time in the manufacturing process.

Based on this type of machine data record, it facilitates maintenance work, preventing breakdowns resulting from the wear and tear of equipment and components. It enables historical analyses of recorded parameters and potential events, which significantly facilitates the improvement of predictive models that prevent service incidents. Service events (date of occurrence, duration, and completion date) are recorded in the Maintenance/Service functional area of the TimeLine system, which also allows for the determination of the life cycle of machines, devices, and components. Based on the analysis results regarding the time and circumstances of wear, it is sufficient to indicate a checkpoint for equipment and individual components – related to the number of products manufactured or the period of use.

In predictive maintenance, machine and equipment parameters must be read and interpreted within a broader context, encompassing a range of elements, such as installations and shop floor conditions. Therefore, alongside MES tools, additional, custom solutions are used to acquire data, such as those related to installation quality, energy consumption, and other utilities. These include IoT (Internet of Things) tools, machine learning and cloud solutions, and flexible low-code technology, which allows for the rapid and simple creation of dedicated applications that complement missing functionality in existing IT infrastructure.

Predicting service events

Acquiring and processing data from multiple sources allows us to identify problems before they result in service events. Predictive maintenance primarily translates into better resource utilization and improved organization of manufacturing processes. By comprehensively analyzing the condition of machines, equipment, and components, we identify components more susceptible to rapid wear and tear, which can be replaced at an early stage without interrupting production. As we know, damage first causes product defects, leading to increased waste, and then equipment failures. Maintenance work conducted this way prevents multiple machines and equipment from being shut down simultaneously, thus maintaining production process continuity. Furthermore, with data on the durability of machine and equipment components, we can select replacement parts that will last longer under specific conditions and operating conditions.

Detailed analysis makes it much easier to detect disruptions, often in areas the technical department hadn't considered and which required corrective action. It's possible to determine whether the cause of failures and malfunctions lies in equipment defects or wear, or whether they stem from environmental conditions, such as installation problems, whose condition may negatively impact the performance of machinery and equipment. Furthermore, it's also possible to determine whether the problems causing maintenance events are recurring and what the circumstances are. This allows for the detection of potential disruptions before they lead to failures or defects and the initiation of appropriate predictive actions.

The benefits of predictive maintenance are numerous, including increased machine and equipment efficiency, increased productivity, and the elimination of unnecessary costs resulting from failures, downtime, or product defects.

Summary

While a quick response to service incidents can reduce potential losses, preventing these types of situations is far more beneficial. This is not only through planned inspections, but above all, through forecasting based on production data.

Predictive maintenance reduces service costs not only by predicting and preventing incidents, but also by rationally performing maintenance work appropriately to the condition of equipment and components, rather than solely according to a pre-determined schedule. Preventive maintenance of machinery and equipment, undertaken before a serious deterioration of the equipment and its components, effectively prevents potentially serious service incidents. And the costs associated with such preventive measures are significantly lower than those associated with having to repair the effects of failures. Therefore, implementing predictive maintenance, along with IT tools for monitoring production processes, is truly an investment that prevents costs that render production unprofitable.